How a Digital Twins Collaboration Improved Timetables for Greater Anglia

Blog written by: Keith Palmer Head of Performance & Planning, Greater Anglia, Dirk Vogt, Strategic Planning / Regional HQ at Toshiba Europe GmbH and Takahisa Yazaki, General Manager of Railway Digital Transformation at Toshiba Digital and Consulting Corporation.

Until recently, the key performance metric for timetable planning focused on the public performance measure (PPM). This is the percentage of trains that run their planned journey, call at all scheduled stations, and arrive at their terminating station within 5-10 minutes of the planned arrival time. A train could arrive late at numerous stations along its route, but still meet this target by making up time before reaching its final stop. The structure of existing timetables has focused on achieving this objective. For CP6, industry has migrated to train punctuality measured to the minute, at all possible scheduled stations on the train’s journey. Timetables designed to achieve PPM may struggle to achieve this, because allowances and dwell-time planned to ensure the end destination is reached on time may not provide enough ‘slack’ to ensure each individual station is reached on time.

In 2018, Greater Anglia (GA) was tasked with planning a new timetable for its West Anglia route (London Liverpool Street to Cambridge), a heavily used commuter route. In the past, GA, like many rail companies, would develop a timetable built on its historical understandings. This time, GA decided to try a data-driven approach to timetable planning: an operational digital twin. To achieve this, GA turned to the expertise of Toshiba, to see if a digital twin of the line could help it meet the new performance metrics.

Enhancing performance with digital twins

Toshiba, already operates numerous Internet of Things (IoT) linked, sensor-enabled manufacturing facilities. They have created digital twins of production lines to develop an understanding of how they perform in real time. Analysis of the data collected allows elaborate real-time visualisation of global processes from beginning to end. On the ground, supervisors and managers become aware of changes instantly, expediting decision-making. The volume of data generated enabled Toshiba to gain insights into the causes of defects and failures within the production systems that had not identified by experienced engineers. Bottlenecks were anticipated, and continuous improvements in yield and productivity were made as the data from the twins was grown and refined. This year, Toshiba and GA applied the knowledge acquired to the complex task of railway timetabling.

New solutions grounded in industry expertise

The project was overseen by Takahisa Yazaki, General Manager of Railway Digital Transformation at Toshiba Digital and Consulting Corporation, and involved an international team from the UK, Japan and Germany. Takahisa believes there are two essential points for developing and operating a digital twin: strong capabilities and knowledge about digital technologies in the cyber world, and industry knowledge and insights into real world operations.

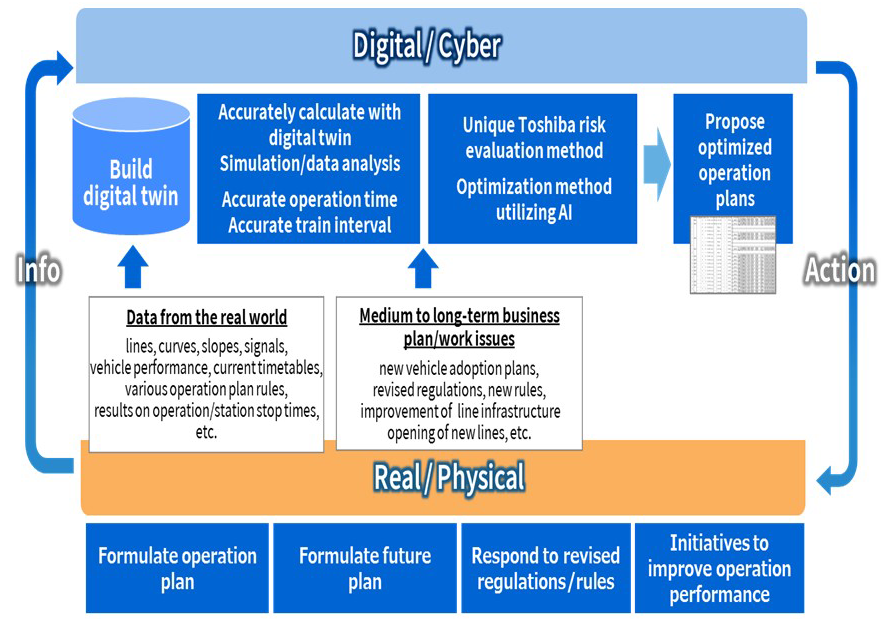

Toshiba and GA brought these resources together in 2019, developing a timetable digital twin. Information fed into the model system included data on stations, platforms, gradients and curves, line speeds and junctions (Figure 1). To create a complete digital representation of the route the performance of rolling stock was also included. Network Rail, a stakeholder in this project, contributed key data.

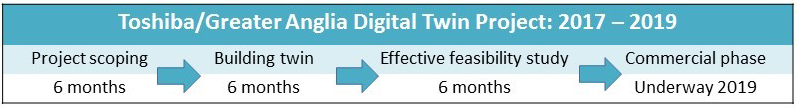

Figure 1: Toshiba’s plan of action to create a digital twin for Greater Anglia

The six-month process of creating the twin saw many challenges, in that an effective structure for the information needed to be identified and implemented comprehensively for each data eco-system represented within the twin. Creating an overarching structure that effectively represented all sub-systems was a great challenge. Additionally, there were familiar challenges, in particular ensuring the appropriate data was available, that it was of good quality, and that ownership of that data was well understood.

To achieve the new punctuality measures required for CP6, allowances and dwell time were planned into the timetable based on the probability that a train may be delayed at a location along its route rather than just its final destination. The real run-time for each section of the journey was calculated within the digital twin, which represented the physical journey across a range of relevant variables. This took into consideration the geometry of the track, the forces impacting running speed when trains were scheduled to pass one another within a tunnel, loading time at different stations. Bringing all of this together allowed the timetable to be planned based on an comprehensive understanding of the route.

The feasibility study for the twin focussed on making the basic elements of the new timetable robust by eliminating the time-consuming and less skilled aspects of the process away from human planners. The aim of the twin was not to replace the human components in the system, but to free them up to focus on the aspects of the task humans are best at: making decisions and being creative.

If timetabling or platform conflicts arose when drawing up the new timetable, the digital twin would identify the error. Applied artificial intelligence (AI) within the digital twin enabled resolutions to complex tasks such as platforming or identification of delay-risk profiles along the route. With the insight provided to GA, planners could focus on adding value to the timetable, which was tested and validated by the digital twin system.

Figure 2: Project timeline

GA consider the trial to have proved the value of this concept with great success, and plan to take the project to the next level by working with Toshiba to map the remaining GA routes by the end of 2019. The digital twin system is expected to be instrumental to any major timetable rewrite in the coming years.

Toshiba are confident that with the twin in place, it will be possible to use the information for other simulations, and plan to link areas such as crew, rolling stock and depots into future versions of the twin. Going forward, Toshiba and GA anticipate extending this project to write error-free timetables completely from scratch.